Hanuman Coming Back Together: CHAPTER SIX

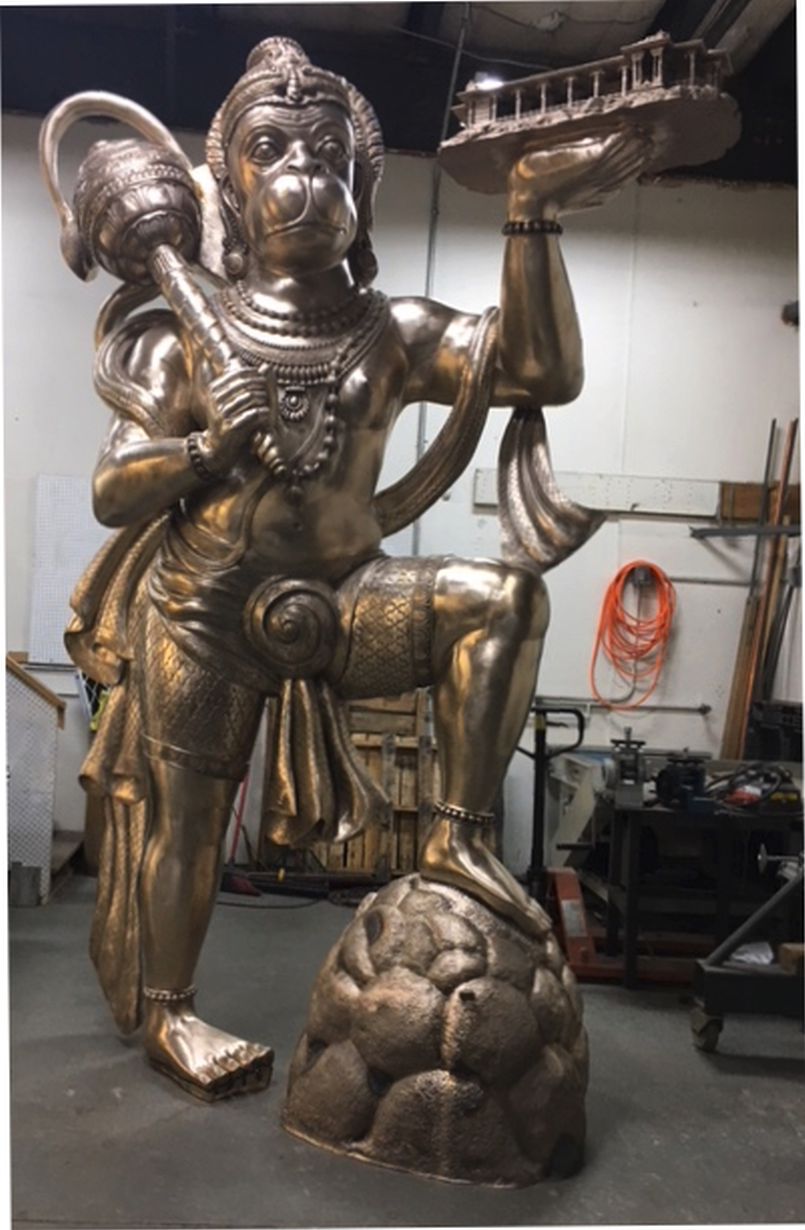

July 14, 2018Once all of the 65 metal pieces are cast, they return to Page Bronze for welding together. It is the job of Bobby Page to do this so perfectly that no one can see where the seams once were.

But first he has to make an armature. This is a framework that will support the statue, which is as we know by now almost entirely empty inside. Bobby used 3" stainless steel pipe for this, making a super-strong structural frame to which the statue will be connected. In the slideshow we show some of this armature.

Piece by piece, Bobby welded the metal sections together, with Gurudeva's photo watching from his workbench just 25 feet away. Every week Bobby sent the monastery some visual updates showing the progress.

One of the questions the monks had was whether the 200-pound model of Iraivan could be held in Hanuman's left hand, or if it would be too heavy. So Bobby's apprentice, Chris, did a test, as the photos reveal.

Bobby completed the welding in early July, just in time for Chapter Seven of our Hanuman's Tail, we mean Tale.

Sculptress Holly Young visits Bobby\

s workshop on one of her many trips to Loveland. They both share a love of Gurudeva\'s teachings and represent, along with Kathy, the core artistic power behind not only Hanuman but all of the monastery bronzes.'

Bobby has just welded the two halves of the face together.

This is the armature, the heavy-duty stainless steel frame that gives the statue its structural integrity. CAT 5 hurricane? No problem!

Slowly the pieces are added and welded to the armature.

Imagine the accuracy required so as not to distort the form.

Kathy and Bobby pose behind their creation.

Bobby gets into his work. Welding the armature inside the mountain on which Hanuman stands.

The underside of the mountain. Note the four bolts in the frame. These, plus two on Hanuman\

s foot, will hold 1-inch stainless steel rods that will go 18 inches into the concrete base when installed on Kauai.'

One of Bobby\

s jobs is to remove not only the metal created by the welding, but the coloration that is caused by the extreme heat. '

Parts await the master.

Hanuman faces a noble future on a far-away island.

To keep the statue still during the process requires major support of chains and pulleys and come-alongs.

Finally, Hanuman stands up. Kathy inspects the details.

A final task is to attach the model of Iraivan, which went to Kauai for a few years when it was thought it would end up in a black granite hand. It was returned to Loveland to end up in a bronze hand.

Bobby prepares to attach it.

One of the small enhancements of the bronze over the granite is that the cloth, front and back, can be dangling naturally in space. On the stone version, to prevent breakage, the cloth had to be attached to the mountain in a slightly unnatural way.

The shipper who will make the crate is making a template of the position of the four bolts inside the mountain. That template was sent to Kauai where it will guide the position of the holes in the base. This has to be exact.

Bobby works to attach the temple. This is a good photo to see the scale of the master work.

Bobby emailed the monastery one morning with this photo, which celebrates a perfectly level temple (not an easy thing to do)

Note Bobby keeps a lot of chains supporting the hand, a precaution in case the added weight will have an impact.

Bobby and Chris

The tests: Chris hangs on to the temple, adding his 180#. Hanuman doesn\

t budge. Whew!'

Can we take the supports off yet?

Done and done.

Sadasivanathaswami and Yogi Rajanatha during last year\

s visit to Loveland to check on progress. Here ends Chapter Six of our story.'

}

];